The two primary styles of pipe threads are National Pipe Thread (NPT) and British Standard Pipe (BSP). But what distinguishes NPT from BSP?

The main distinction is not about the superiority or application of one type of thread over the other, but rather their geographic usage: NPT threads are prevalent in the United States and Canada, whereas BSP threads are commonly found in the United Kingdom and many regions in Europe, Asia, and Africa.

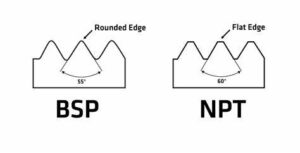

So, what are the key differences between NPT and BSP threads? How can you differentiate between them? The primary difference lies in the thread angles: NPT threads have a 60-degree angle, while BSP threads feature a 55-degree angle. Additionally, the crests and roots of NPT threads are pointed, whereas those of BSP threads are rounded.

Can BSP Be Used with NPT?

Can you connect a fitting with BSP threads to a pipe with NPT threads if they are the same size? NPT and BSP pipes are not compatible. NPT threads have pointed crests and roots, in contrast to BSP’s rounded ones. Furthermore, the thread angle difference—60 degrees for NPT versus 55 degrees for BSP—results in different pitches. Attempting to connect them will lead to misalignment, damage, and potential leaks.

In high-stakes environments, like the oil and gas industry where pressures can reach up to 15,000 pounds per square inch (psi), a leaking connection can have catastrophic consequences. This is why using BSP and NPT threads together is strongly discouraged.

However, if you need to connect a BSP pipe to an NPT pipe or fitting, adapters are available, including:

- NPT female to BSP male

- BSP female to NPT male

- NPT female to BSP female

- BSP female to NPT female (same as above)

How to Identify BSP vs NPT Threads

As previously mentioned, BSP and NPT threads differ in thread angles and pitches, but identifying them can still be tricky, especially with smaller ½-inch pipes or fittings.

To differentiate between BSP and NPT, check for tapering. BSP threads are typically straight or parallel, while NPT threads are tapered. If the threads are of the same size, they are likely BSP; if the first thread has a smaller diameter than the last, it is NPT.

This tapering is why NPT threads are often referred to as National Thread Taper, or American threads, while BSP threads are known as British threads.

Summary of NPT vs BSP Differences

| Aspect | NPT (National Pipe Taper) | BSP (British Standard Pipe) |

|---|---|---|

| Terminology | Commonly known as NPT threads. | Also referred to as BSP threads. |

| Origin | Developed in the U.S.; used in North America. | Originated in the U.K.; used in Europe and worldwide. |

| Thread Angle | 60 degrees | 55 degrees |

| Thread Shape | Tapered (conical) | Tapered (conical) |

| Thread Direction | Right-hand | Right-hand |

| Sealing Mechanism | Relies on thread interference fit; typically uses Teflon tape or pipe dope. | Relies on thread interference fit; typically uses sealing compound or tape. |

| Compatibility | Not compatible with BSP threads. | Not compatible with NPT threads. |

| Use Cases | Common in plumbing, HVAC, and industrial applications in North America. | Widely used in plumbing, automotive, pneumatic systems, and industrial applications. |

| Standard Sizes | Available in various fractional and nominal sizes. | Available in various metric and imperial sizes. |

| Common Applications | Found in residential and commercial plumbing, water, and gas systems. | Used in automotive, hydraulic systems, and industrial machinery. |

| Standards | Conforms to ANSI/ASME B1.20.1 and ASTM standards. | Conforms to BS 21 and ISO 7 standards. |

NPT vs BSP Chart

| Nominal Size | Thread Density (per inch) NPT | Thread Density BSP) | NPT(Inches) | BSP (mm) |

| 1/16 | 27 | 28 | 0.037 | 0.907 |

| 1/8 | 27 | 28 | 0.037 | 0.907 |

| 1/4 | 18 | 19 | 0.055 | 1.337 |

| 3/8 | 18 | 19 | 0.055 | 1.337 |

| 1/2 | 14 | 14 | 0.071 | 1.814 |

| 3/4 | 14 | 14 | 0.071 | 1.814 |

| 1 | 11 1/2 | 11 | 0.086 | 2.309 |

| 1 1/4 | 11 1/2 | 11 | 0.086 | 2.309 |

| 1 1/2 | 11 1/2 | 11 | 0.086 | 2.309 |

| 2 | 11 1/2 | 11 | 0.086 | 2.309 |

Additional Thread Types: NPT vs NPS

In the U.S., there are other thread forms that may cause confusion, such as National Pipe Straight (NPS). The difference between NPT and NPS is that NPT threads are tapered, while NPS threads are straight or parallel, although they share the same thread angle, shape, and pitch.

This similarity can make it challenging to differentiate between NPS and BSP, as both have parallel threads. While both possess distinct thread angles and pitches, recognizing them can still be difficult.

Tapered threads generally provide a better seal due to maximum pressure on the threads, necessitating a sealant like Teflon tape or pipe dope. Conversely, parallel threads, such as NPS, require a gasket or rubber O-ring for sealing.

While NPT and NPS threads can engage, they do not form a reliable seal and should not be used together due to potential leaks.

NPT vs NPTF

National Pipe Taper Fuel (NPTF) shares similarities with NPT but is engineered to provide a better, leak-free connection without the need for a thread sealant. NPTF threads have the same thread angle, pitch, taper, shape, and length, but their crests and roots are adjusted for an interference fit to eliminate leak paths.

BSP vs BSPT

The difference between British Standard Pipe (BSP) and British Standard Pipe Taper (BSPT) is that BSP threads are parallel while BSPT threads are tapered. Despite having the same thread angle, pitch, and shape, distinguishing between BSPT and NPT threads can be challenging without examining the thread angle or the sharpness of the crests and roots.

BSP threads are often referred to as BSPP (British Standard Pipe Parallel), indicating parallel threads, while BSPT denotes tapered threads. For connections using BSP threads, a rubber washer, O-ring, or gasket is required to create a seal, while BSPT connections need a thread sealant like Teflon tape.

When using Teflon tape, ensure to wrap it clockwise; otherwise, it may unravel during connection, leading to leaks. For more information, check out Topol Power.