In the dynamic realm of industrial applications, SAE fittings are essential components. From the 45-degree SAE style to specialized fittings for air conditioning, these vital connectors ensure robust, leak-resistant connections across various pressure scenarios. However, selecting the right fittings can be intricate.

In this blog post, we explore the complexities of SAE fittings. We’ll break down critical aspects such as thread sizes, Tube O.D., and different types of fittings, including SAE Brass Flare Connectors and flared brass fittings. Whether you’re a small business owner, part of a large organization, or a DIY enthusiast, join us as we delve into the fascinating world of SAE fittings, equipping you with the knowledge for your next project.

What Are SAE Fittings?

SAE fittings are specialized connectors designed for diverse industrial uses, named after the Society of Automotive Engineers (SAE) that establishes common standards for flare fittings. These standards ensure optimal performance, durability, and safety.

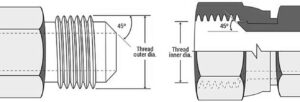

Key parameters include thread form, tube sizes, seat angle, and pressure ratings, all crucial for creating strong, leak-resistant connections in fluid and gas transfer systems. The fittings often comprise a male and female connection, where the male fitting features external threads (Thread O.D.) and the female has internal threads (Female Thread I.D.). This design allows secure connections for tubes or hoses, typically involving a flared tubing end that matches the tapered seat in the female fitting.

Widely utilized in industries such as automotive, hydraulics, and air conditioning, SAE fittings provide reliable connections essential for high-pressure applications. The right selection depends on factors like tube material (e.g., aluminum or copper), pressure requirements, and specific applications.

Types of SAE Fittings

SAE Brass Flare Fittings come in various types, each tailored for specific industrial needs. These include JIC (Joint Industry Council) fittings, ORFS (O-Ring Face Seal), and 45-degree SAE flare fittings.

– JIC Fittings: Known for their robust metal-to-metal seal, JIC fittings feature a 37.5-degree flare, making them ideal for high-pressure hydraulic applications.

– ORFS Fittings: These fittings excel in leak resistance due to an O-ring in a groove on the fitting’s flat face, capable of handling higher pressures, perfect for hydraulic systems.

– 45 Degree SAE Flare Fittings: Common in automotive and refrigeration systems, these fittings ensure a dependable seal by matching the tube flare with the female fitting’s conical seat.

SAE 45° Flare – SAE J512 Threads Dimensions

The SAE 45° Flare fittings are commonly used for low pressure applications such as refrigerant lines, fuel lines, and automotive piping systems. Both the SAE male and female halves have a 45° flare seat. The threads of the two halves engage to form a strong mechanical connection. The seal is formed on the 45° flare seat. Except for the seat angles, the SAE 45° Flare fittings are identical to JIC 37° Flare fittings.

| MALE THREAD OD | DASH SIZE | MALE THREAD OD (mm) | FEMALE THREAD ID (mm) | TUBE SIZE (inch) |

| 5/16 x 24 | -05 | 7.9 | 6.8 | 1/8 |

| 3/8 x24 | -06 | 9.5 | 8.4 | 3/16 |

| 7/16×20 | -07 | 11.1 | 9.9 | 1/4 |

| 1/2×20 | -08 | 12.7 | 11.4 | 5/16 |

| 5/8×18 | -10 | 15.9 | 14.2 | 3/8 |

| 3/4×16 | -12 | 19.1 | 17.5 | 1/2 |

| 7/8×14 | -14 | 22.2 | 20.6 | 5/8 |

| 1.1/16×14 | -17 | 27.0 | 24.9 | 3/4 |

Choosing the Right SAE Fittings

To ensure optimal performance and safety, consider several factors when selecting SAE fittings:

– Type of Application: Different fittings serve various functions; understanding your application is key to choosing correctly.

– Material Compatibility: Ensure that the fitting material matches the tubing material for a secure connection.

– Pressure Ratings: Select fittings rated for the required pressure to maintain system efficiency and safety.

– Size: The fitting size should correspond with the Tube O.D. to guarantee a proper fit.

– Thread Type: Familiarize yourself with thread types, as they affect sealing and connection strength.

Installing and Maintaining SAE Fittings

Correct installation and maintenance of SAE fittings are vital for their longevity and effectiveness:

– Installation: Match the thread sizes of the male and female parts and ensure proper alignment to avoid cross-threading. Follow manufacturer guidelines for tightening.

– Maintenance: Regular inspections can detect leaks or wear early. Keep fittings clean and consider material-specific care, especially for brass fittings to prevent corrosion.

By understanding and applying these principles, you can ensure the reliable performance of SAE fittings in your industrial applications.