NPT and NPTF are widely adopted standard thread designs in various industries. For piping, NPT threading adheres to ANSI B1.20.1, while NPTF follows ANSI B1.20.3. This article delves into the differences between NPT and NPTF, and compares NPT with other thread designs such as NPS, JIC, and MIP.

Overview of NPT and NPTF

NPT stands for National Pipe Taper, whereas NPTF stands for National Pipe Taper for Fuels. Both thread designs are utilized in applications ranging from electrical conduits to high-pressure piping for hydrocarbons and aggressive liquids. The tapered design of both threads ensures solid, vibration-resistant connections. They share the same taper-per-inch, threads-per-inch, and pitch diameters, but there are several distinctions, as outlined in the following table.

Differences Between NPT and NPTF

| Parameter | NPT | NPTF |

|---|---|---|

| Function | General-purpose tapered thread | Dry seal tapered thread |

| Thread Crest | Larger range | More consistent |

| Thread Root | Clearance with mating threads | Interference with mating threads |

| Seal | Requires sealant to prevent leaks | Mechanical seal, no sealant needed |

| Gauge Requirement | Same for sizes ≤ 3/8 inch, differs for sizes ≥ ½ inch | Varies primarily in diameter requirements |

| Inspection | Requires single gauge | Needs multiple gauges |

Interchangeability of NPT and NPTF

Due to their similar taper design, NPT and NPTF can fit together. However, because of differences in diameters and thread configurations, using a sealant is necessary to prevent leakage. Interchanging them is not recommended for sizes ½ inch and above due to varying gauge requirements.

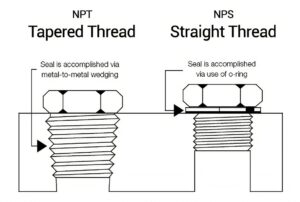

NPT vs NPS

NPT and NPS (National Pipe Straight) share a 60° thread angle and the same threads per pitch. However, NPT is tapered while NPS has a parallel cross-section. This fundamental difference means NPS requires a gasket or O-ring for sealing, which is less effective than the tapered seal provided by NPT. While the threads may engage due to the same angle, their sealing capabilities do not align, making interchangeability inadvisable.

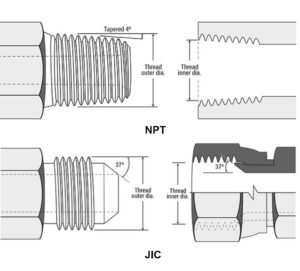

NPT vs JIC

NPT and JIC (Joint Industry Council) originate from different standards (ANSI B1.20.1 for NPT and SAE J514 for JIC). The key differences include:

| Feature | NPT | JIC |

|---|---|---|

| Thread Type | Tapered | Parallel |

| Thread Angle | 60° | 37° flare angle |

| Sealing Method | Relies on thread taper | Superior sealing capability |

| Pressure Suitability | Low-pressure applications | High-pressure applications |

Interchanging NPT and JIC fittings is not feasible due to sealing reliability concerns.

NPT vs MIP

MIP stands for Male Iron Pipe, with its counterpart being FIP (Female Iron Pipe). Despite having identical thread dimensions, NPT and MIP differ in the following aspects:

| Parameter | NPT | MIP |

|---|---|---|

| Material | Plastic, PVC | Iron, copper, steel, PVC |

| Application | Low-pressure applications | High-pressure applications |

| Thread Shape | Tapered | Straight |

| Sealant | Sealant compound or PTFE tape | Pipe dope or Teflon tape |

Understanding these differences can aid in selecting the appropriate thread design for specific applications and ensuring leak-proof connections.