Have you ever ordered the wrong pipe size and found yourself confused about how it happened? You might have measured the pipe threads multiple times before placing your order, yet when the pipe arrives, it doesn’t fit. Although measuring pipe threads seems straightforward, it can actually be quite tricky. A few adjustments in your measuring technique could save you time and prevent frustration.

The most widely used threads in general applications adhere to the American National Standard Pipe Thread (NPT) standards. These include both tapered threads, commonly used for fasteners and piping, and straight thread series.

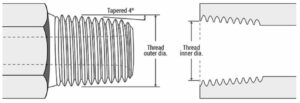

Tapered threaded pipes, often utilized in plumbing for fluid or steam delivery, have a conical thread shape. This design creates a seal when tightened, as the threads compress against one another.

On the other hand, straight thread fittings connect pipes but don’t create a seal on their own. To ensure a proper seal, straight threads require Teflon tape or pipe compound when connected to a female pipe. For specific advice on measuring NPT, read on.

Feel free to reach out to us today to discuss your needs or to schedule an onsite consultation at Topol Power.

A general rule of thumb for measuring National Pipe Thread is to subtract ¼ inch from your initial measurement. The thickness of the pipe wall can vary, so it’s essential to take this into account.

For instance, when measuring the threads on a ¼ inch male pipe thread (MPT), measure the outer edges of the thread and then subtract ¼ inch from that measurement to account for the wall thickness on both sides. When measuring a female pipe thread (FPT), measure the outer diameter (OD) of the pipe itself and subtract ¼ inch to determine the correct pipe thread size.

An easier method is to use a caliper, which measures both the OD and the inside diameter (ID). Eaton Weatherhead provides an angle gauge caliper and thread pitch gauge to assist with this.

Refer to the chart below for guidance on measuring National Pipe Threads (NPT). For additional information on other pipe threads, check out the reference guide from Eaton Weatherhead.

National Pipe Tapered (NPT) Thread Chart

Measure the thread diameter and subtract ¼ inch to find the nominal pipe size.

| Inch Size | Dash Size | Nominal Thread Size | Male Thread O.D. (in) |

Female Thread I.D. (in) |

| 1/8 | 2 | 1/8×27 | 0.39 | 0.33 |

| 1/4 | 4 | 1/4×18 | 0.52 | 0.44 |

| 3/8 | 6 | 3/8×18 | 0.65 | 0.58 |

| 1/2 | 8 | 1/2×14 | 0.81 | 0.7 |

| 3/4 | 12 | 3/4×14 | 1.02 | 0.92 |

| 1 | 16 | 1×11/2 | 1.28 | 1.16 |

| 1 1/4 | 20 | 1 1/4 x11 1/2 | 1.62 | 1.5 |

| 1 1/2 | 24 | 1 1/2×11 1/2 | 1.86 | 1.73 |

| 2 | 32 | 2×11 1/2 | 2.33 | 2.22 |

Additional Common Pipe Thread Acronyms

-NPT: National Pipe Thread (tapered)

– FPT: Female Pipe Thread (interchangeable with NPT)

– FIP: Female Iron Pipe (interchangeable with NPT)

– MPT: Male Pipe Thread (interchangeable with NPT)

– MIP: Male Iron Pipe (interchangeable with NPT)

– IPS: Iron Pipe Size (interchangeable with NPT)

– PTF: SAE Short Taper Pipe Thread

– NPTF: National Pipe Thread Fuel (American National taper pipe thread for dryseal pressure-tight joints)

– NPSM: National Pipe Straight Mechanical (American National straight pipe thread for mechanical joints)

– NPSI: American National Straight Intermediate Pipe Thread

– GHT: Garden Hose Thread

– NST: National Standard Thread (fire hose thread)

– BSPT: British Standard Taper Pipe Thread (metric)

For non-NPT measurements, many people mistakenly measure a pipe by its outside diameter. For instance, if you measure the pipe’s diameter and see a 1-inch reading, you might assume you need a 1-inch pipe. However, this often leads to mismatched fittings. In reality, you should order a ¾-inch pipe because the diameter should refer to the inside of the pipe, where flow occurs, rather than the outside that you measured. Remember to focus on the interior diameter for accurate sizing.